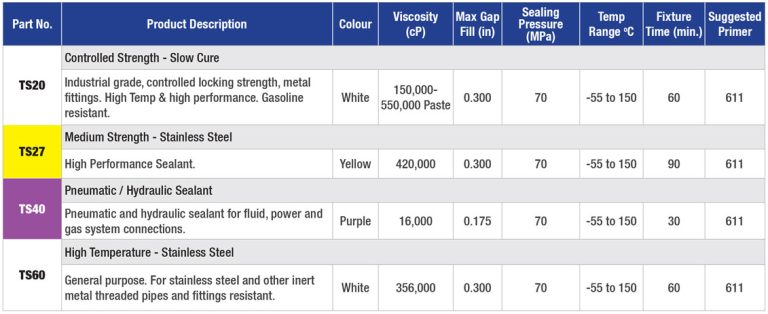

Kemtite Thread Sealants seals and secures metal pipes and fittings, by filling the space between threaded metal parts. Thread sealants prevents leakage caused by tape shredding, vibration loosening, solvent evaporation, and damaged threads.

Kemtite sealants are designed for both low and high-pressure applications. Thread sealants seal to the burst strength of most piping systems. Because of the lubricating properties, Kemtite thread sealants make it easy to assemble fittings as well as prevent galling of the threads. For repairs, parts may be disassembled with basic hand tools.

An anaerobic thread sealing and thread locking compound with PTFE for pipe fittings. It is designed for sealing threaded fasteners that required disassembly with standard hand tool. It exhibits good temperature and solvent resistant.

Key Features

Medium Strength

Provides reliable holding power while allowing for easy disassembly with standard hand tools.

Stainless Steel Compatibility

Optimized with stainless steel and other passive metals.

Leakage Prevention

Effectively seals threaded connections to prevent leakage.

Vibration Resistance

Effectively seals threaded connections to prevent leakage.Offers excellent resistance to vibration and shock, maintaining the integrity of the seal.

Corrosion Protection

Protects against rust and corrosion, extending the lifespan of threaded components.

An anaerobic thread sealant is particularly suitable for Stainless steel. Designed to prevent leakage and vibrations.

Key Features

Medium Strength

Ensures a strong yet removable seal, allowing for disassembly with standard hand tools.

Stainless Steel Compatibility

Perfectly suited for stainless steel and other passive metal surfaces.

Leakage Prevention

Provides an effective seal to prevent any fluid leakage.

Vibration Resistance

Maintains seal integrity even under heavy vibrations and shocks.

Corrosion Protection

Protects threaded connections from rust and corrosion, extending their lifespan.

Kemtite TS40 is a Medium Strength Stainless Steel Thread Sealant, it is a fast-curing high strength anaerobic sealant which seals hydraulic and pneumatic fittings up to 2” diameter, resisting high pressures and vibrational loosening. It is best suited for fluid, power and gas systems connections.

Key Features

Fast-Curing

Ensures rapid sealing for efficient assembly.

High Strength

Provides robust sealing capability under high pressures.

Leakage Prevention

Provides an effective seal to prevent any fluid leakage.

Vibration Resistance

Maintains seal integrity in dynamic applications.

Fluid Compatibility

Resists a wide range of fluids commonly found in hydraulic and pneumatic systems.

Sets fast to give an instant low-pressure seal of 100 psi and a high-pressure seal when fully cured. This high strength product provides 100% sealing capability and does not shrink after curing, unlike more traditional solvent based pipe dopes. Contains PTFE. It is best suited for stainless steel and other inert metal threaded pipes and fittings.

Key Features

High-Temperature Resistance

Withstands extreme temperatures, ensuring reliable sealing in high-heat environments.

Fast Setting

Provides instant low-pressure sealing and achieves high-pressure sealing upon full cure.

High Strength

Offers robust sealing for critical applications.

PTFE Enhanced

Contains PTFE for enhanced sealing performance.

No Shrinkage

Does not shrink after curing, maintaining seal integrity over time.

With years of experience in chemical formulations, we specialise in high-performance thread sealants tailored to industrial needs.

Our rigorously tested products meet the highest performance, reliability, and safety standards.

We offer solutions that seamlessly integrate into your operations and are customised to specific requirements.

We offer solutions that seamlessly integrate into your operations and are customised to specific requirements.

We minimise environmental impact without compromising quality.

They are used on pipes to prevent leaks when pressure is applied and to ensure that pipes do not leak fluids while connecting one pipe with another.

The selection is determined by the connected materials, the operational conditions (temperature, pressure), and the ease of removal.

A number of materials could be used with thread sealants, including metals, plastics, and composites. When picking the right sealant for your particular application, compatibility is key.

Yes, our thread sealants can withstand various extreme temperatures and chemicals, guaranteeing their reliability for longer periods of time.

As indicated in the manufacturer’s instructions, clean and dry threads should be sealed with thread sealant compounds before charging the system with pressure.

© Copyright 2025 All rights reserved.